ELECTRONICS

Circuit Verification

Comprehensive ICT solutions to verify component placement, soldering quality, and circuit integrity. Ensures early detection of faults to maintain high manufacturing standards.

Performance Validation

Validates the performance of assembled PCBs under real-world conditions. Detects the functional errors before when product dispatch, ensuring the reliability and given compliance.

Firmware Programming

High-speed automated flashing of firmware onto electronic boards. Supports multiple device types, guaranteeing accurate programming and reducing production time.

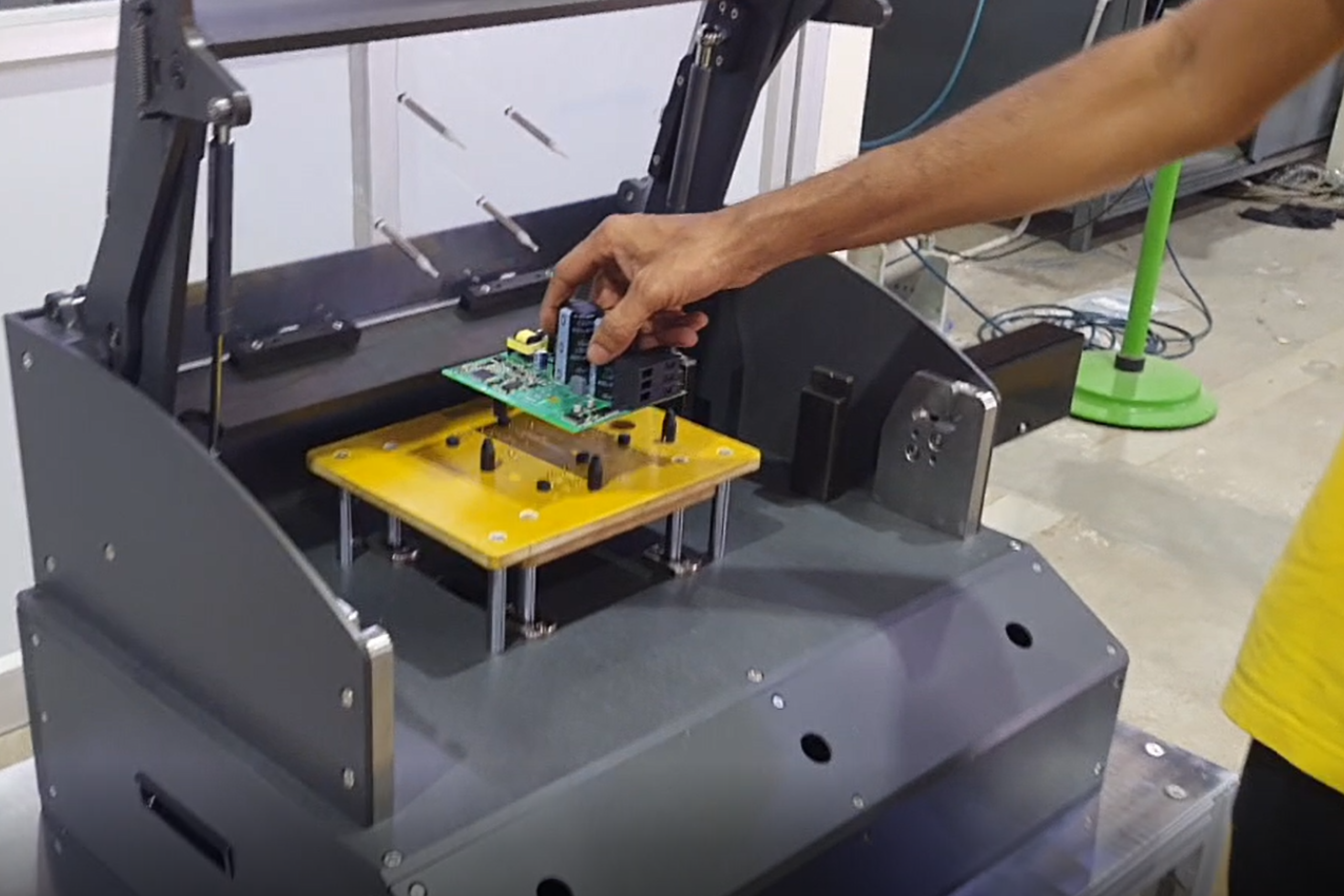

PCB

ICT Testing

Our process includes rigorous In-Circuit Testing (ICT), a crucial step to ensure the functionality and quality of each PCB. Using advanced bed-of-nails fixtures, we check individual components for electrical parameters such as shorts, opens, resistance, and capacitance.

- Component Verification

- Electrical Accuracy

- Defect Detection

- High Efficiency

- Quality Assurance

- Automated Testing

PCB

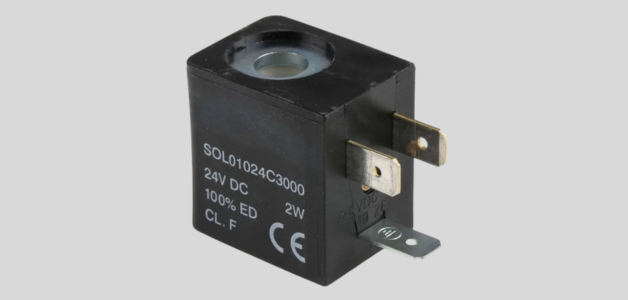

Flash kit

We provide advanced Flash Kit programming services to streamline production and save time. Our solutions enable efficient and accurate programming of microcontrollers and other programmable components directly on the PCB. This ensures that each board is loaded with the required firmware and software, making it ready for immediate deployment in its final application.

- Efficient Programming

- High Accuracy

- Reliable Output

- Microcontroller Support

- Streamlined Production

- Ready-to-Use Boards

PCB

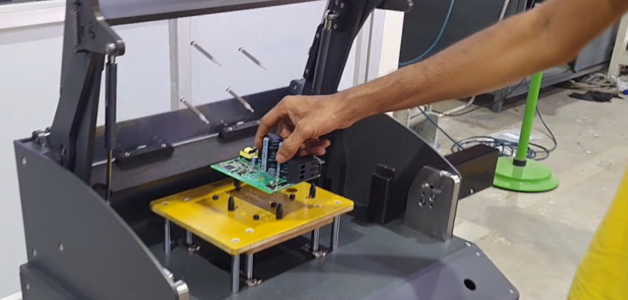

Test jig & Fixtures

Our PCB Test Jigs & Fixtures are designed to ensure precise and reliable testing of electronic assemblies. Built with high-quality materials and customized layouts, they provide stable connections for accurate signal measurement. These fixtures help streamline the testing process, minimize human error, and improve overall product validation efficiency.

- Custom Design

- Stable Connections

- Durable Build Quality

- Easy Maintenance

- High Testing Accuracy

- Quick Setup & Operation