AUTOMOTIVE

ENGINE PERFORMANCE

Advanced valve control enhances fuel efficiency, power output, and smooth engine operation under varying driving conditions.

EMISSIONS CONTROL

Optimized pressure regulation supports compliance with global emission standards while reducing environmental impact.

SAFETY & RELIABILITY

Precision-tested valves ensure that consistent performance in braking, steering, and safety-critical automotive systems.

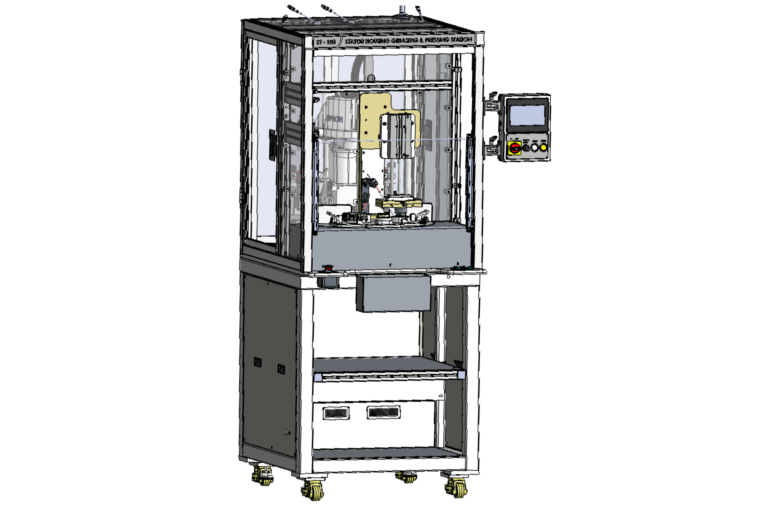

Automotive switches

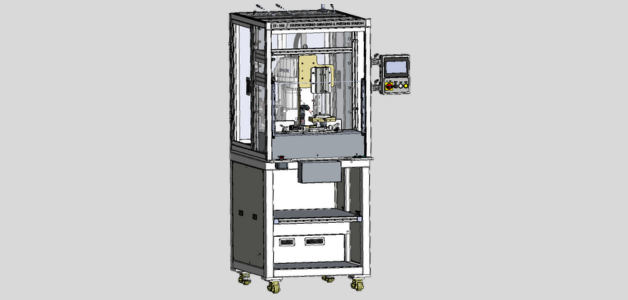

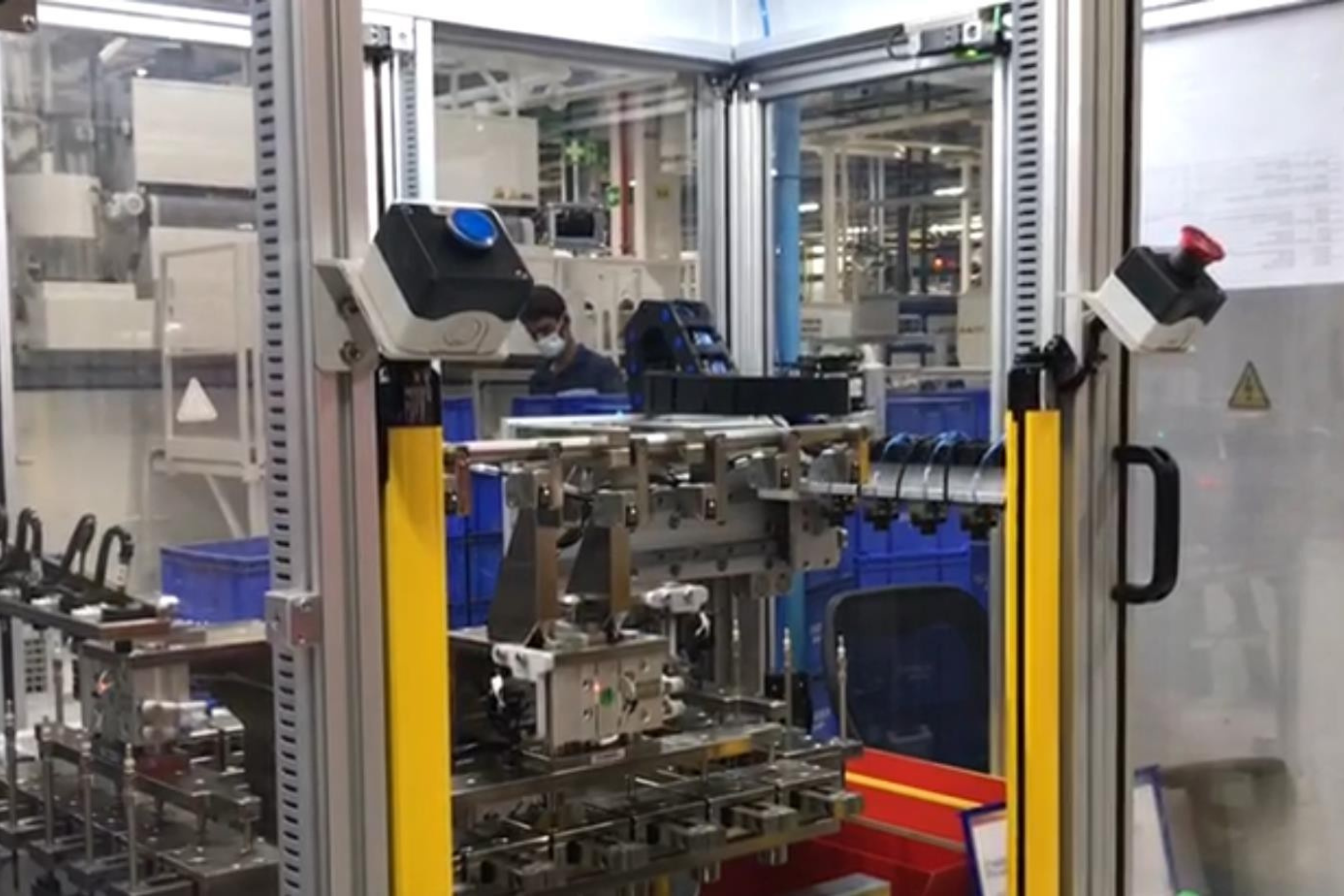

ASSEMBLY LINE & EOLT

Automotive switches are precisely assembled and tested at the End-of-Line stage to ensure durability, accuracy, and safety in every vehicle application.

- Fast Assembly

- Electrical Test

- Durability Check

- Mechanical Test

- Safety Standard

- Fault Detection

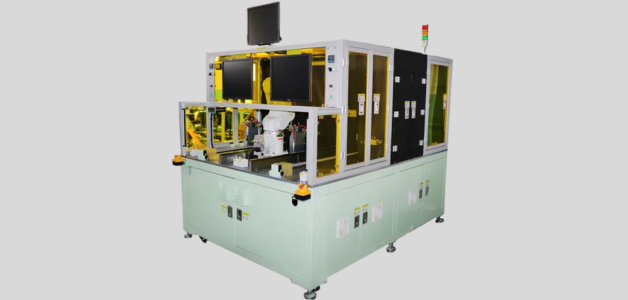

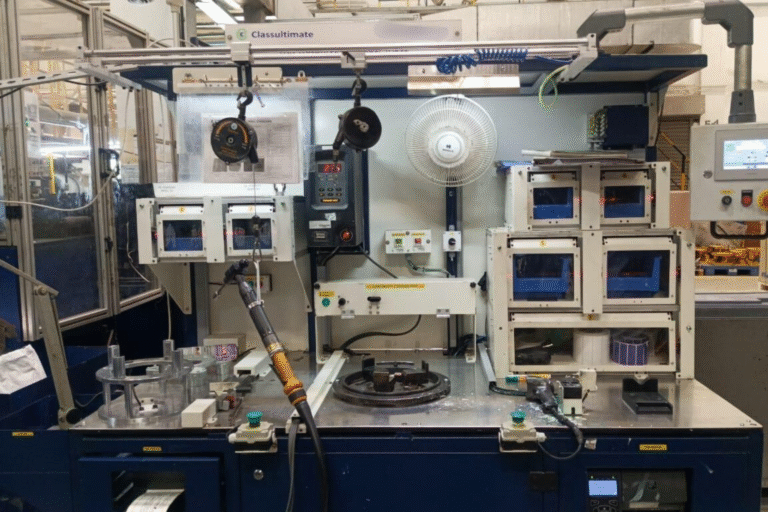

Steering column Unit

ASSEMBLY LINE & EOLT

Steering column units are thoroughly assembled and end-of-line tested to guarantee smooth handling, reliability, and compliance with automotive safety standards.

- Precise Assembly

- Torque Testing

- Durability Check

- Alignment Control

- Fault Detection

- Performance Test

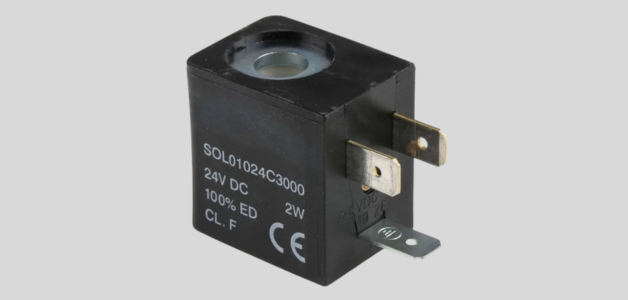

Test box for automotive switches

Standalone testing kit for automotive switches

A dedicated standalone testing kit designed to verify the functionality, reliability, and durability of automotive switches with quick and accurate results.

- Compact Design

- Plug & Play

- Quick Testing

- Durability Check

- Safety Assurance

- Error Detection

Cooling fan drive

ASSEMBLY LINE

Assembly line setup for precise mounting, testing, and quality inspection of automotive cooling fan drives, ensuring durability and optimal performance.

- Auto Alignment

- Torque Testing

- Vibration Check

- Speed Calibration

- Quality Inspection

- Safety Sensors

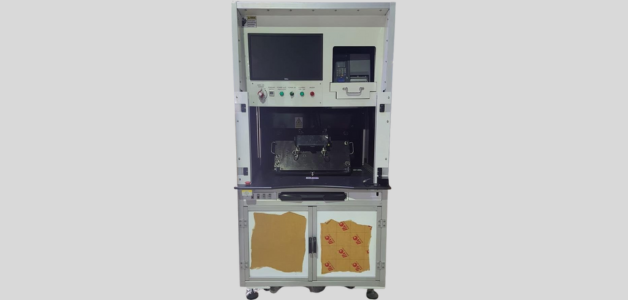

Glow plug

Performance testing Machine

Machine designed for testing glow plugs performance, verifying heating efficiency, durability, and response time under simulated engine conditions.

- Heating Test

- Response Check

- Voltage Monitoring

- Durability Test

- Auto Diagnostics

- Safety Controls

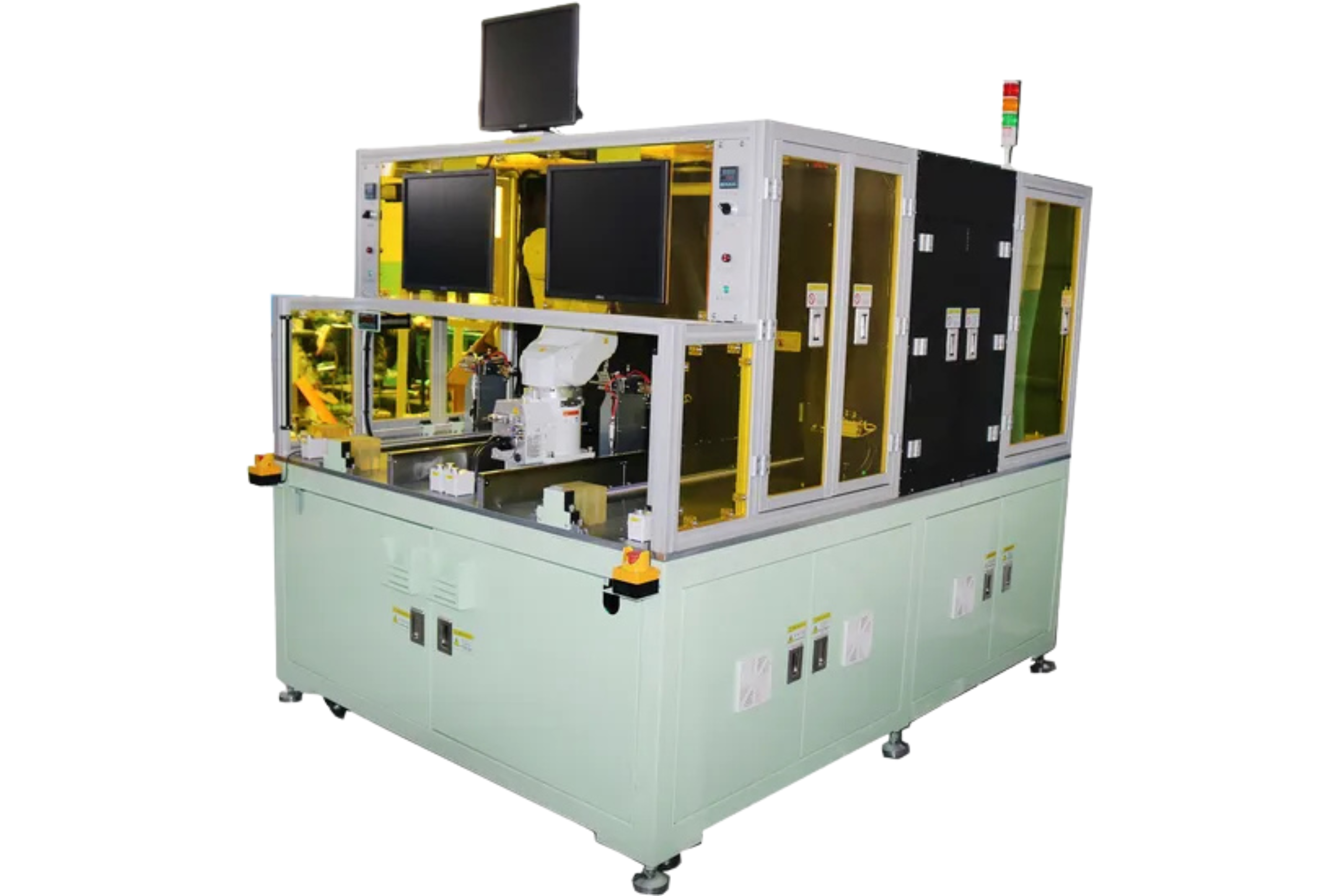

Automotive display cluster

EOLT

End-of-line testing (EOLT) system for automotive display clusters, ensuring all indicators, gauges, and lighting functions operate accurately before final assembly.

- Function Check

- Backlight Test

- Signal Verification

- Gauge Accuracy

- Connectivity Test

- Error Detection

Shark fin Antenna

EOLT

End-of-line testing (EOLT) system for shark fin antennas, ensuring signal reception, connectivity, and durability meet automotive standards before installation.

- Signal Test

- Connectivity Check

- Durability Test

- Frequency Range

- Auto Diagnostics

- Error Detection

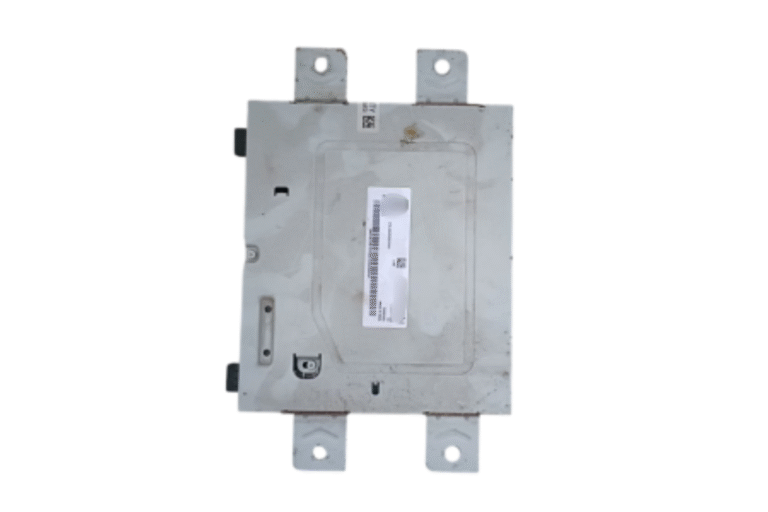

Silver Box

EOLT

Automated testing platforms for Silver Box units, performing electrical, thermal, and communication validations. Our EOLT ensures every product meets OEM reliability and performance standards before vehicle integration.

- Electrical Validation

- Thermal Testing

- Communication Check

- Fault Detection

- Auto Diagnostics

- OEM Compliance

Automotive USB Charger

EOLT

EOLT solutions for automotive USB chargers ensure safe charging performance, electrical compliance, and durability under varying load conditions, guaranteeing customer satisfaction and adherence to regulatory standards.

- Load Testing

- Safety Check

- Voltage Monitoring

- Durability Test

- Compliance Verification

- Fault Detection

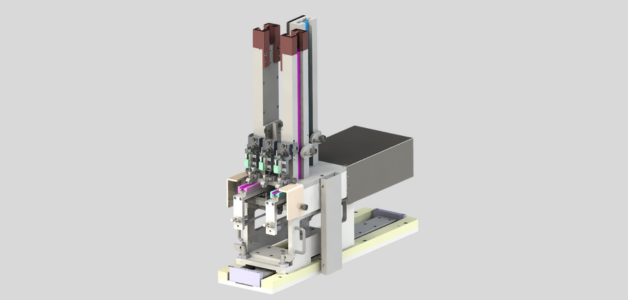

Clutch pad

Strap Feeder

An automated strap feeder system that handles clutch pads with precision, minimizing operator dependency and boosting line productivity. It ensures consistent positioning and smooth integration into subsequent processing or assembly stages.

- Auto Feeding

- Precision Handling

- Position Accuracy

- Operator-Free

- Smooth Integration

- Productivity Boost