General Engineering

Automation Solutions

Designing and implementing automated systems to the improve efficiency, and reduce manual intervention, and optimizing industrial processes.

Material Analysis

Conducting detailed material testing and analysis to select the right materials for durability, performance, and cost-effectiveness in engineering projects.

Maintenance & Support

Providing ongoing maintenance, troubleshooting, and technical support to ensure long-term and smooth operation of engineering systems.

PCB

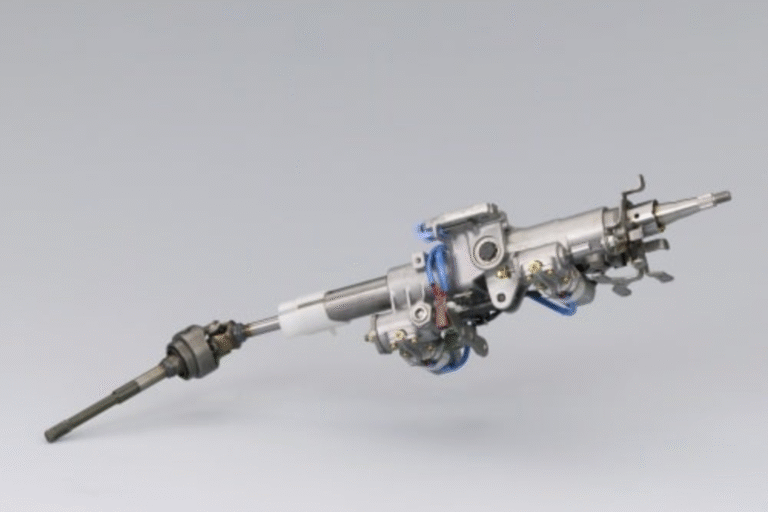

Impeller

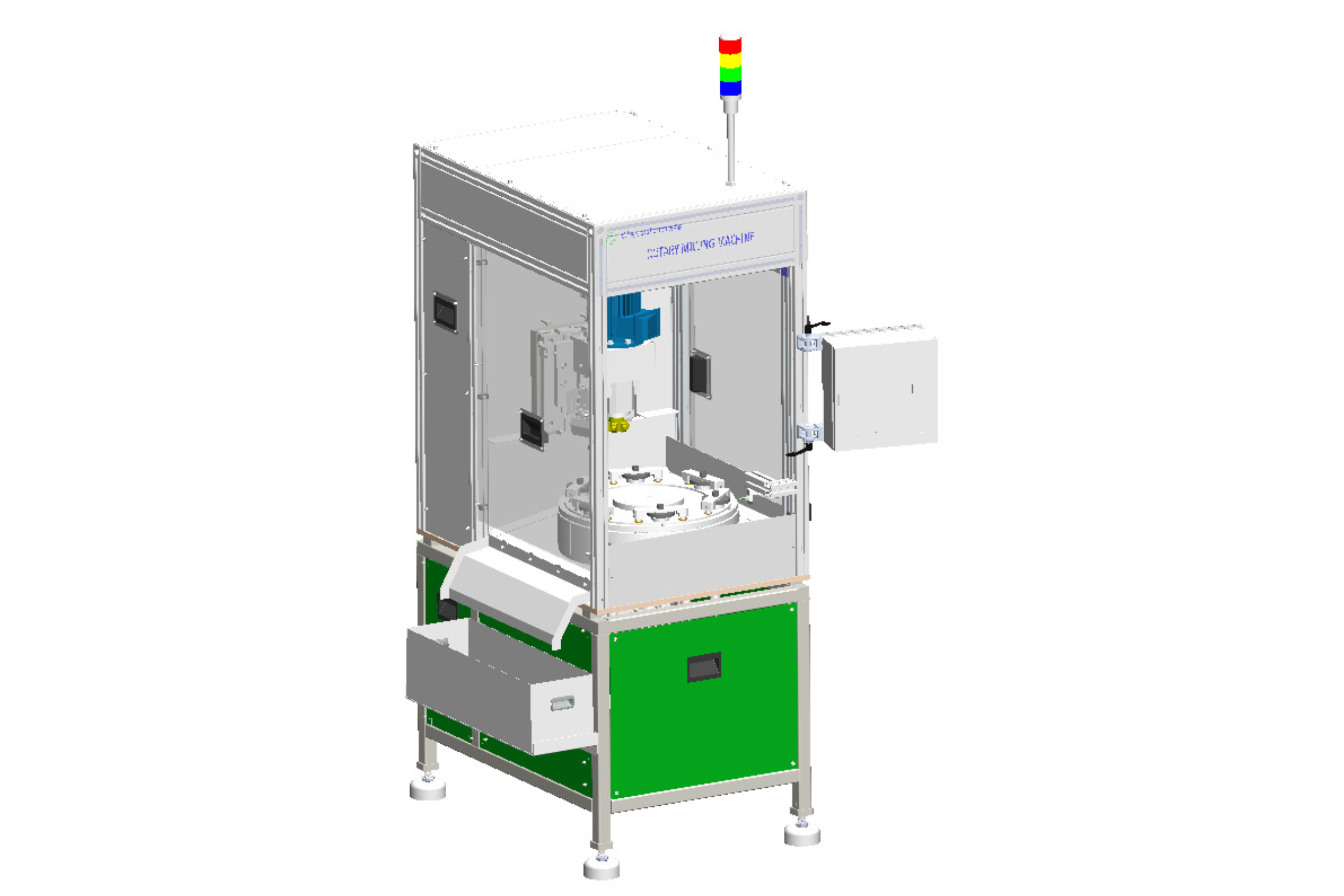

Our Rotary and Linear milling machines are used to achieve precise, flat surfaces and maintain tight tolerances on impellers. This precision machining ensures a perfect fit for the main body and hub, providing balanced operation and reducing wear and vibration.

- Precision Machining

- Tight Tolerances

- Balanced Operation

- Rotary & Linear Milling

- Secure Assembly

- Durable Finish

Filters

Filter cutting press

We provide specialized solutions for filter production using our precision cutting press. The machine accurately cuts filter media to exact specifications, ensuring uniform size and shape for reliable filtration. This process is essential for applications across automotive, industrial air, and fluid filtration systems.

- Precise Cutting

- Uniform Shape

- High Efficiency

- Versatile Applications

- Reduced Waste

- Reliable Performance

Casting components

Non stick coating spraying machine

Our non-stick coating spraying machine provides uniform and durable coatings on cast components. This ensures easy release, reduced friction, and enhanced corrosion resistance, making it ideal for applications in food processing, industrial molds, and other demanding environments.

- Uniform Coating

- Durable Finish

- Reduced Friction

- Easy Release

- Efficient Application

- Versatile Use

PVC Pipes

Inline Pipe weighing Machine

Our PVC pipe production line incorporates an inline pipe weighing machine to continuously monitor pipe weight and density during manufacturing. This ensures uniform wall thickness and material distribution, maintaining the structural integrity and consistent quality of every pipe produced.

- Continuous Monitorin

- Consistent Quality

- Material Optimization

- Structural Integrity

- High Accuracy

- Efficient Production